Achieving superior Direct-to-Film (DTF) print quality requires a meticulous approach to optimizing print settings. The first step in this process is to ensure that the printer is properly calibrated. Calibration involves adjusting the printer settings to match the specific characteristics of the film and ink being used. This can be done by running test prints and making incremental adjustments to parameters such as color balance, ink density, and resolution. By fine-tuning these settings, you can achieve a more accurate and vibrant print output.

Another crucial aspect of optimizing print settings is selecting the appropriate print resolution. Higher resolutions generally result in better print quality, but they also require more time and resources. It is important to find a balance between quality and efficiency. For most DTF applications, a resolution of 1440 dpi (dots per inch) is sufficient to produce sharp and detailed images. However, for prints that require extremely fine details, such as intricate designs or small text, a higher resolution may be necessary.

In addition to resolution, the choice of ink plays a significant role in determining print quality. DTF printing typically uses pigment-based inks, which offer excellent color vibrancy and durability. However, not all pigment inks are created equal. It is essential to use high-quality inks that are specifically formulated for DTF printing. These inks are designed to adhere well to the film and produce consistent, long-lasting results. Using subpar inks can lead to issues such as color fading, poor adhesion, and reduced print longevity.

The type of film used in DTF printing also impacts the final print quality. There are various types of films available, each with its own set of characteristics. For instance, some films are designed to produce a glossy finish, while others offer a matte appearance. The choice of film should be based on the desired look and feel of the final product. Additionally, it is important to ensure that the film is compatible with the printer and ink being used. Incompatible films can lead to issues such as poor ink adhesion, smudging, and reduced print quality.

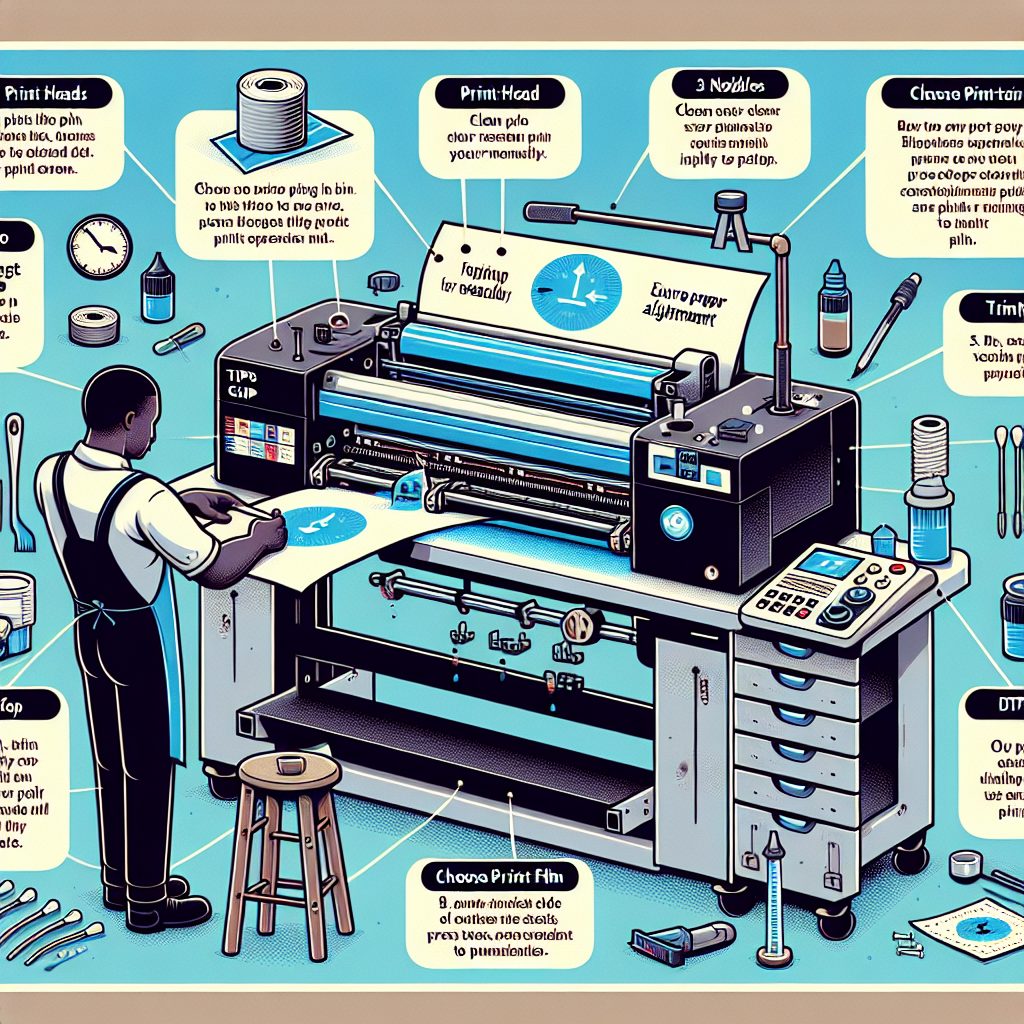

Proper maintenance of the printer is another key factor in achieving superior DTF print quality. Regular cleaning and maintenance help prevent issues such as clogged nozzles, ink buildup, and mechanical wear. It is recommended to follow the manufacturer's guidelines for routine maintenance, which may include tasks such as cleaning the print heads, replacing worn parts, and performing software updates. By keeping the printer in optimal condition, you can ensure consistent and high-quality print results.

Furthermore, the environment in which the printing takes place can also affect print quality. Factors such as temperature, humidity, and dust levels can impact the performance of the printer and the quality of the prints. It is advisable to maintain a controlled environment with stable temperature and humidity levels. Additionally, keeping the printing area clean and free from dust can help prevent contamination of the film and ink, leading to better print quality.

In conclusion, optimizing print settings for superior DTF quality involves a combination of proper calibration, selecting the right resolution, using high-quality inks and films, maintaining the printer, and controlling the printing environment. By paying attention to these factors and making necessary adjustments, you can achieve consistently high-quality DTF prints that meet your expectations and those of your clients.

Selecting the right transfer film and adhesive powder is crucial for achieving high-quality Direct-to-Film (DTF) prints. The choice of these materials can significantly impact the final output, influencing factors such as color vibrancy, durability, and overall finish. To begin with, understanding the different types of transfer films available in the market is essential. Transfer films come in various thicknesses and finishes, including matte, glossy, and semi-glossy. Each type has its unique properties and is suited for different applications. For instance, a glossy film might be ideal for designs that require a shiny, reflective finish, while a matte film could be better for a more subdued, professional look.

When selecting a transfer film, it is also important to consider its compatibility with your printer and ink. Not all films work well with every type of ink, and using an incompatible film can lead to issues such as poor adhesion, color bleeding, or even damage to the printer. Therefore, it is advisable to consult the printer manufacturer’s guidelines or seek recommendations from experienced users in the DTF printing community. Additionally, conducting small test prints can help identify any potential issues before committing to a large batch.

Equally important is the choice of adhesive powder. The adhesive powder plays a critical role in ensuring that the ink adheres properly to the fabric, providing durability and washability to the final print. There are different grades of adhesive powder, each designed for specific types of fabrics and printing requirements. For example, a high-tack adhesive powder might be necessary for printing on fabrics with a rough texture, while a low-tack powder could suffice for smoother materials. It is also worth noting that the particle size of the adhesive powder can affect the print quality. Finer particles tend to provide a smoother finish, whereas coarser particles might be more suitable for designs that require a textured effect.

To achieve optimal results, it is essential to apply the adhesive powder evenly across the printed film. Uneven application can lead to inconsistent adhesion, resulting in areas where the print may peel off or fade over time. Using a shaker or a similar tool can help distribute the powder uniformly. Moreover, the curing process, which involves heating the adhesive powder to activate its bonding properties, should be carefully controlled. Overheating or underheating can compromise the adhesive’s effectiveness, leading to subpar print quality.

Furthermore, the environment in which the DTF printing process takes place can also influence the outcome. Factors such as humidity, temperature, and cleanliness can affect both the transfer film and adhesive powder. High humidity levels, for instance, can cause the adhesive powder to clump, making it difficult to achieve an even application. Maintaining a controlled environment and ensuring that the workspace is free from dust and contaminants can help mitigate these issues.

In conclusion, selecting the right transfer film and adhesive powder is a multifaceted process that requires careful consideration of various factors. By understanding the properties of different films and powders, ensuring compatibility with your printer and ink, and maintaining a controlled printing environment, you can significantly enhance the quality of your DTF prints. Taking the time to experiment with different materials and techniques will ultimately lead to more consistent and professional results, making your DTF printing endeavors more successful and rewarding.

Proper maintenance and calibration of Direct-to-Film (DTF) printers are crucial for achieving high-quality prints and ensuring the longevity of the equipment. To begin with, regular cleaning of the printer is essential. Dust, ink residue, and other debris can accumulate over time, leading to clogged nozzles and reduced print quality. Therefore, it is advisable to clean the print heads and other critical components periodically. Using manufacturer-recommended cleaning solutions and tools can help prevent damage and maintain optimal performance.

In addition to cleaning, it is important to monitor the humidity and temperature of the printing environment. DTF printers are sensitive to environmental conditions, and fluctuations can affect print quality. Maintaining a stable environment with controlled humidity levels can prevent issues such as ink drying out or smudging. Investing in a hygrometer and a dehumidifier or humidifier, depending on your local climate, can be beneficial in achieving the ideal conditions for your printer.

Another key aspect of maintaining DTF printers is the regular replacement of consumables. Ink cartridges, print heads, and other consumable parts have a limited lifespan and can degrade over time. Keeping track of their usage and replacing them as needed can prevent unexpected breakdowns and ensure consistent print quality. It is also important to use high-quality consumables that are compatible with your specific printer model. Substandard or incompatible products can cause damage and negatively impact print results.

Calibration is another critical factor in enhancing DTF print quality. Regularly calibrating your printer ensures that colors are accurate and prints are sharp. This process involves adjusting various settings such as color profiles, print head alignment, and media feed. Many DTF printers come with built-in calibration tools and software that guide users through the process. Following the manufacturer's instructions and performing calibration tests can help achieve the best possible results.

Furthermore, it is essential to stay updated with the latest firmware and software updates for your DTF printer. Manufacturers often release updates that include bug fixes, performance improvements, and new features. Keeping your printer's firmware and software up to date can enhance its functionality and ensure compatibility with the latest printing technologies. Regularly checking the manufacturer's website or subscribing to their newsletter can help you stay informed about available updates.

In addition to these technical aspects, proper handling and storage of printing materials are also important. DTF films and transfer powders should be stored in a cool, dry place to prevent moisture absorption and degradation. Handling these materials with clean hands and avoiding contact with contaminants can prevent issues such as poor adhesion and print defects. Using high-quality DTF films and transfer powders that are specifically designed for your printer can also contribute to better print quality.

Lastly, it is beneficial to keep a log of maintenance activities and print settings. Documenting the cleaning schedule, calibration results, and any issues encountered can help identify patterns and address recurring problems. This log can also serve as a reference for troubleshooting and optimizing print settings for different types of projects.

In conclusion, proper maintenance and calibration of DTF printers are essential for achieving high-quality prints and ensuring the longevity of the equipment. Regular cleaning, monitoring environmental conditions, replacing consumables, calibrating the printer, staying updated with firmware and software, handling materials properly, and keeping a maintenance log are all important practices that contribute to efficient and effective DTF printing. By following these tips, users can enhance their print quality and maximize the performance of their DTF printers.