Direct-to-Film (DTF) printing technology has been making waves in the textile and apparel industry, offering a versatile and efficient alternative to traditional printing methods. As we look ahead to the next decade, several innovative breakthroughs are poised to redefine the landscape of DTF printing, bringing both exciting opportunities and formidable challenges. To begin with, advancements in ink formulations are expected to play a pivotal role in the evolution of DTF printing. Researchers are tirelessly working on developing eco-friendly, water-based inks that not only reduce environmental impact but also enhance print quality and durability. These new inks promise to offer vibrant colors and improved washability, making them ideal for a wide range of applications, from fashion to home textiles. Moreover, the integration of nanotechnology into ink development is set to revolutionize the industry by enabling finer detail and sharper images.

In addition to ink innovations, the next decade will likely see significant improvements in printing hardware. The development of high-speed, high-resolution DTF printers is already underway, aiming to meet the growing demand for quick turnaround times without compromising on quality. These next-generation printers are expected to feature advanced print heads and automated maintenance systems, reducing downtime and increasing overall efficiency. Furthermore, the incorporation of artificial intelligence and machine learning into DTF printing systems will enable predictive maintenance and real-time quality control, ensuring consistent output and minimizing waste.

Another area where DTF printing is expected to make strides is in substrate compatibility. Currently, DTF printing is primarily used on cotton and polyester fabrics, but ongoing research aims to expand its applicability to a broader range of materials, including blends and synthetic fibers. This expansion will open up new markets and applications, allowing businesses to offer a more diverse range of products. Additionally, the development of flexible and stretchable inks will enable DTF printing on performance fabrics, catering to the growing demand for activewear and athleisure.

While these innovations hold great promise, they also bring a set of challenges that the industry must address. One of the primary concerns is the cost of adopting new technologies. Small and medium-sized enterprises (SMEs) may find it difficult to invest in the latest DTF printers and inks, potentially widening the gap between large corporations and smaller players. To mitigate this, industry stakeholders must explore financing options and collaborative models that make advanced DTF technology accessible to all.

Another challenge lies in the environmental impact of DTF printing. Although strides are being made in developing eco-friendly inks, the industry must also focus on sustainable practices throughout the production process. This includes reducing energy consumption, minimizing waste, and implementing recycling programs for used transfer films and other consumables. By adopting a holistic approach to sustainability, the DTF printing industry can contribute to a greener future while maintaining its competitive edge.

In conclusion, the next decade promises to be a transformative period for DTF printing technology, marked by groundbreaking innovations and new opportunities. Advancements in ink formulations, printing hardware, and substrate compatibility will drive the industry forward, offering enhanced quality and efficiency. However, these developments also come with challenges that must be addressed to ensure sustainable growth. By embracing innovation and fostering collaboration, the DTF printing industry can navigate these challenges and unlock its full potential, paving the way for a vibrant and dynamic future.

Direct-to-Film (DTF) printing technology has emerged as a revolutionary force in the textile and garment industry, offering unparalleled versatility and efficiency. However, like any burgeoning technology, DTF printing is not without its challenges. Overcoming these obstacles is crucial for businesses aiming to leverage the full potential of DTF printing. By understanding the common issues and implementing strategic solutions, companies can navigate the complexities of this innovative technology and achieve success.

One of the primary challenges in DTF printing is ensuring consistent print quality. Variations in temperature, humidity, and even the type of film used can significantly impact the final output. To address this, it is essential to maintain a controlled environment where these variables are closely monitored. Investing in high-quality equipment that offers precise temperature and humidity control can mitigate many of these issues. Additionally, using premium-grade films and inks specifically designed for DTF printing can enhance the consistency and vibrancy of the prints.

Another significant hurdle is the adhesion of the printed film to the fabric. Poor adhesion can result in prints that peel or crack after washing, undermining the durability and appeal of the final product. To overcome this, it is crucial to use a high-quality adhesive powder that is compatible with both the film and the fabric. Conducting thorough pre-treatment of the fabric, such as cleaning and pre-pressing, can also improve adhesion. Moreover, experimenting with different heat press settings to find the optimal temperature and pressure for each fabric type can ensure a strong bond between the film and the textile.

The speed and efficiency of the DTF printing process are also areas where challenges frequently arise. While DTF printing is generally faster than traditional methods, bottlenecks can occur during the curing and transfer stages. To enhance efficiency, businesses can invest in advanced curing systems that offer faster and more uniform drying. Implementing automated workflows and integrating DTF printers with other production systems can streamline operations and reduce downtime. Regular maintenance and calibration of equipment are also vital to prevent unexpected breakdowns and ensure smooth, uninterrupted production.

Color accuracy and consistency are critical for producing high-quality prints, yet they can be difficult to achieve with DTF printing. Variations in ink formulation, printer settings, and even the type of fabric can lead to discrepancies in color output. To tackle this issue, it is important to use color management software that can calibrate and profile the printer for different substrates. Regularly updating the software and firmware of the printer can also help maintain color accuracy. Additionally, conducting test prints and making necessary adjustments before full-scale production can prevent costly errors and ensure that the final product meets the desired color specifications.

Finally, the environmental impact of DTF printing is a growing concern. The use of synthetic films and chemical adhesives can contribute to waste and pollution. To address this, companies can explore eco-friendly alternatives such as biodegradable films and water-based inks. Implementing recycling programs for used films and adopting sustainable practices throughout the production process can also reduce the environmental footprint of DTF printing.

In conclusion, while DTF printing technology presents several challenges, strategic solutions and proactive measures can effectively address these issues. By focusing on maintaining print quality, improving adhesion, enhancing efficiency, ensuring color accuracy, and adopting sustainable practices, businesses can overcome the obstacles associated with DTF printing. Embracing these strategies will not only lead to successful implementation but also position companies at the forefront of innovation in the textile and garment industry.

Direct-to-Film (DTF) printing technology has been making waves in the textile and apparel industry, offering a versatile and efficient alternative to traditional printing methods. As we look to the future, several emerging trends and technologies are poised to further revolutionize this space, bringing both exciting innovations and formidable challenges.

One of the most significant trends in DTF printing is the continuous improvement in print quality and durability. Advances in ink formulations and film materials are enabling sharper, more vibrant prints that can withstand repeated washing and wear. These enhancements are crucial for meeting the high standards of both consumers and businesses, who demand not only aesthetic appeal but also longevity in their printed products. Moreover, the development of eco-friendly inks and biodegradable films is addressing growing environmental concerns, making DTF printing a more sustainable option.

In tandem with these material advancements, the integration of artificial intelligence (AI) and machine learning (ML) is transforming the operational efficiency of DTF printing. AI-driven software can optimize print settings, predict maintenance needs, and even automate design adjustments, reducing the margin for error and minimizing downtime. This level of automation is particularly beneficial for small to medium-sized enterprises (SMEs) that may lack the resources for extensive manual oversight. Consequently, AI and ML are not only enhancing the quality of prints but also making the technology more accessible and cost-effective.

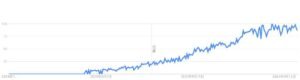

Another emerging trend is the increasing adoption of DTF printing in niche markets and custom applications. From personalized apparel and promotional items to intricate designs on unconventional substrates, the versatility of DTF printing is opening new avenues for creative expression and business opportunities. This trend is further amplified by the rise of e-commerce platforms that cater to custom and on-demand printing services, allowing consumers to easily access and order unique, high-quality products.

However, these innovations are not without their challenges. One of the primary obstacles is the need for continuous research and development to keep pace with rapidly evolving technologies. Companies must invest in R&D to stay competitive, which can be a significant financial burden, especially for smaller players in the market. Additionally, the integration of advanced technologies like AI and ML requires specialized knowledge and skills, posing a barrier to entry for businesses that lack technical expertise.

Furthermore, the environmental impact of DTF printing, despite improvements, remains a concern. While eco-friendly inks and films are a step in the right direction, the industry must also address issues related to energy consumption and waste management. Developing more energy-efficient printers and establishing robust recycling programs are essential steps toward mitigating the environmental footprint of DTF printing.

In conclusion, the future of DTF printing is marked by a dynamic interplay of innovations and challenges. Advances in print quality, AI integration, and market diversification are driving the technology forward, offering exciting possibilities for businesses and consumers alike. However, the industry must navigate the complexities of continuous R&D, technical expertise, and environmental sustainability to fully realize the potential of DTF printing. As these trends continue to unfold, stakeholders must remain agile and forward-thinking, embracing both the opportunities and the challenges that lie ahead.